Fumes depuration plant

The respect for the environment is one of the main commitments of For.Tec., which constantly develops and updates the technologies for reducing emissions into the atmosphere to be installed on incineration and cremation facilities, that are built here.

All For.Tec. incinerators are equipped with suitable systems for flue gas depuration, which not only ensure emissions fully complying with regulations in force, but they ensure also the protection of the environment in all operating circumstances.

The emissions abatement systems and methods most commonly used on our installations are:

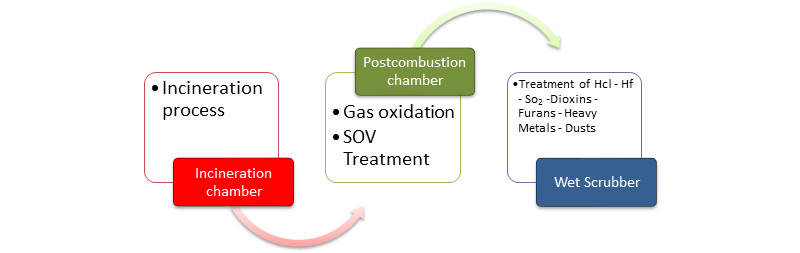

Wet Scrubber: it is the best available technology for the depuration of flue gas coming from incineration of organic waste, animal carcasses and slaughterhouse waste and it is a suitable technology to depurate flue gas from incineration of hospital waste or waste containing small amounts of halogenated, when the installation is Extra EU. The system is easy to install and maintain and it requires small space..

Recommended for:

• Organic waste Incineration

• Slaughterhouse waste and whole animals carcasses Incineration

• Pet crematories

• Corpses crematories

• Hospital and industrial waste Incineration (Extra EU Zone)

"Dry" systems for pollutants abatement: they are systems designed to break down any type of pollutant, even in presence of large quantities of plastics and halogenated, with the assurance of full respect of the most restrictive European and Worldwide limits. It is possible to add to these dry systems some systems for the recovery of the energy from flue gases, to produce hot water, hot air, steam or diathermic oil.

Recommended for:

• Hospital and industrial waste Incinerations

• Corpses crematories

• Hazardous waste incineration

Incineration chamber

Thermal destruction process

Postcombustion chamber

Gas oxidation

Treatment of COV

Heat exchanger for temperature reduction

Usually both fumes/air heat exchangers are used; from this process, the thermal energy can be recovered and used for multiple applications

Reagents Injection System - Reaction Tower for acidic components abatement

According to the exact pollutants to be removed, it will be chosen the appropriate reagents; the most commonly used are Lime, Activated Carbon, Sorbalite, Ammonia, etc.

Dedusting by sleeve or bag filters

Sleeve filters are successfully used, besides for dust removal, also for the chemical absorption of acid gases such as HF, HCI and SO2 and for the adsorption of dioxins/furans and heavy metals, such as Hg and its compounds

Gas extraction and ejection into the atmosphere

By means of electric fan and chimney