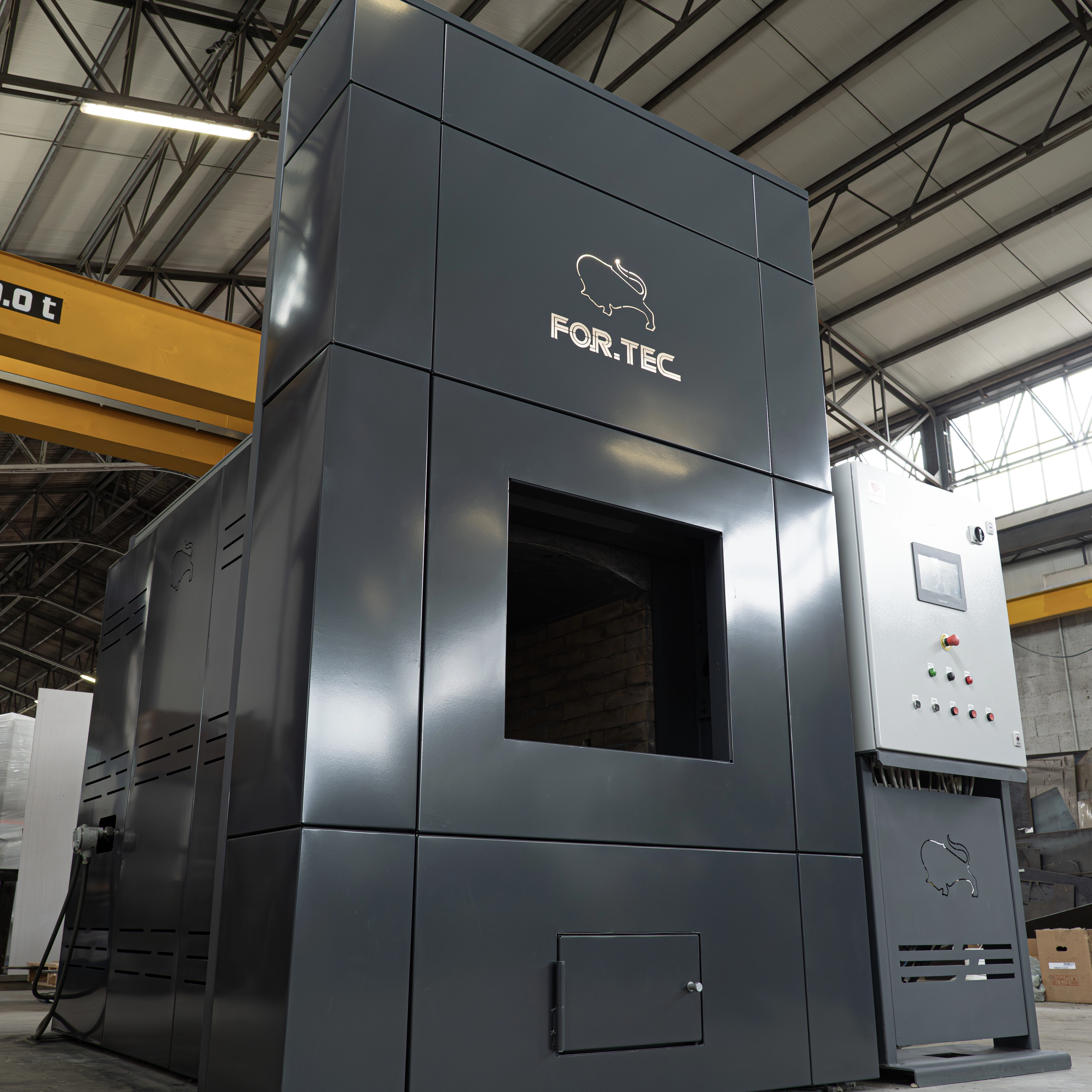

Pet crematories mod. FD 4.0

Devotion to our work, along with the passion and great respect we have always had for pets, fostered us to develop a specially designed cremation system to accompany pets remains on their last journey in the most delicate and elegant way possible.

Great attention to details, high quality finishes and process automation, which is achieved thanks to the latest technological developments and a software designed following decades of experience in the field, they make our oven mod. FD 4.0 the top of the range of pet crematory ovens, which are currently on both the Italian and European market, effective and fully compliant with the most restrictive National and International environmental requirements.

The cremation chamber, with a volume of 0.8 cubic meters, allows an easy treatment of large animals and at the same time the cremation with ashes separation of up to 4 animals per cycle.

The hot sole of the cremation chamber speeds up the cremation process, especially in the presence of frozen animals and avoids the stagnation of liquids at the base of the oven, which are often difficult to treat.

The walls in common between the cremation chamber and the postcombustion chamber lead to a constant heat exchange between them and so, to the recovery of a large amount of heat, which otherwise would have to be dissipated outside of the oven; the result of this process is a considerable fuel saving compared to traditional ovens.

The installation of two-stage burners in cremation chamber and in postcombustion chamber make it possible to correctly manage the flame and the temperatures both in the case of small animals single cremation and in the case of multiple cremations, avoiding continuous and expensive shutdowns and re-ignitions of burners.

On each Crematory oven mod. FD 4.0, in addition to postcombustion chamber, a SCRUBBER type emission reduction system is installed as standard, to intervene on powders and water-soluble acids compounds, in order to guarantee emissions that fully comply with Italian and European most restrictive standards.

The cremation process takes place in a completely automated way thanks to the Siemens PLC with a high resolution Touch Screen Panel, managed by For.Tec. software, which gives the possibility to make the system remote, and so allowing to take advantage of a timely remote assistance service, enabling accurate diagnostics and thus limiting the need for costly downtime and on-site maintenance.

An intuitive synoptic allows you to control the entire process and manage the cremation of pets with extreme ease.

The system can be integrated with the Company's management software; it is possible to track every cremation at any time by receiving completed cycle notice on email or SMS.

Thanks to the accessories that we are able to provide with the oven, such as automated carcasses loading system, ash shredding system, waste ashes aspirator, cold carcasses storage rooms etc., opening a new business will be extremely easy.

Latest generation technology

◽ Touch Screen with Siemens PLC

◽ Hot sole technology

◽ Low consumption

◽ Remote Support

By investing in the purchase of our oven mod. FD 4.0 you’ll be able to create new business opportunities, such as:

• Single or collective pets Cremations, with ashes return to the respective owners

• Incineration of deceased pets, without return of the ash to the owners

• Incineration of carcasses from veterinary laboratories, kennels, farms or zooprophylactic institutes

• Disposal of carcasses of animals which died on the roads

Our Pet Crematory ovens mod. FIDO are built in full compliance with the provisions of Commission Regulation (EU) No. 142/2011 of 25 February 2011, implementing Regulation (EC) No 1069/2009 of the European Parliament and repealing provisions Regulation EC 1774/2002.